system-integration-tips

System integration tips from Fab Lab Ísafjörður

Here are a few tips that might be useful for System integration week in the Fab Academy:

Nice prototyping

Quote from Dan Gelbart:

I cannot overemphasise the importance of making everything with keyholes and slots and captive hardware. If you spend all your life in R&D you’ll spend about one year of your life taking screws out of covers, so if you do it in slots, it’s the same as extending your life by the same amount of health food plus exercise extends your life, and it’s much simpler.

Dan Gelbart’s classic notes on quick prototyping: Part 1, Part 2

Dan says that you can prototype just about anything with a waterjet cutter (because it cuts through any material with good precision), a press brake and some welding tools. Take a look at the examples in his notes, they’re fantastic.

Packaging

A nice example of the importance of packaging:

| Virtual detents were developed by Jesse Schoch: | But the method didn't become popular until it was packaged as the SmartKnob by Scott Bezek: |

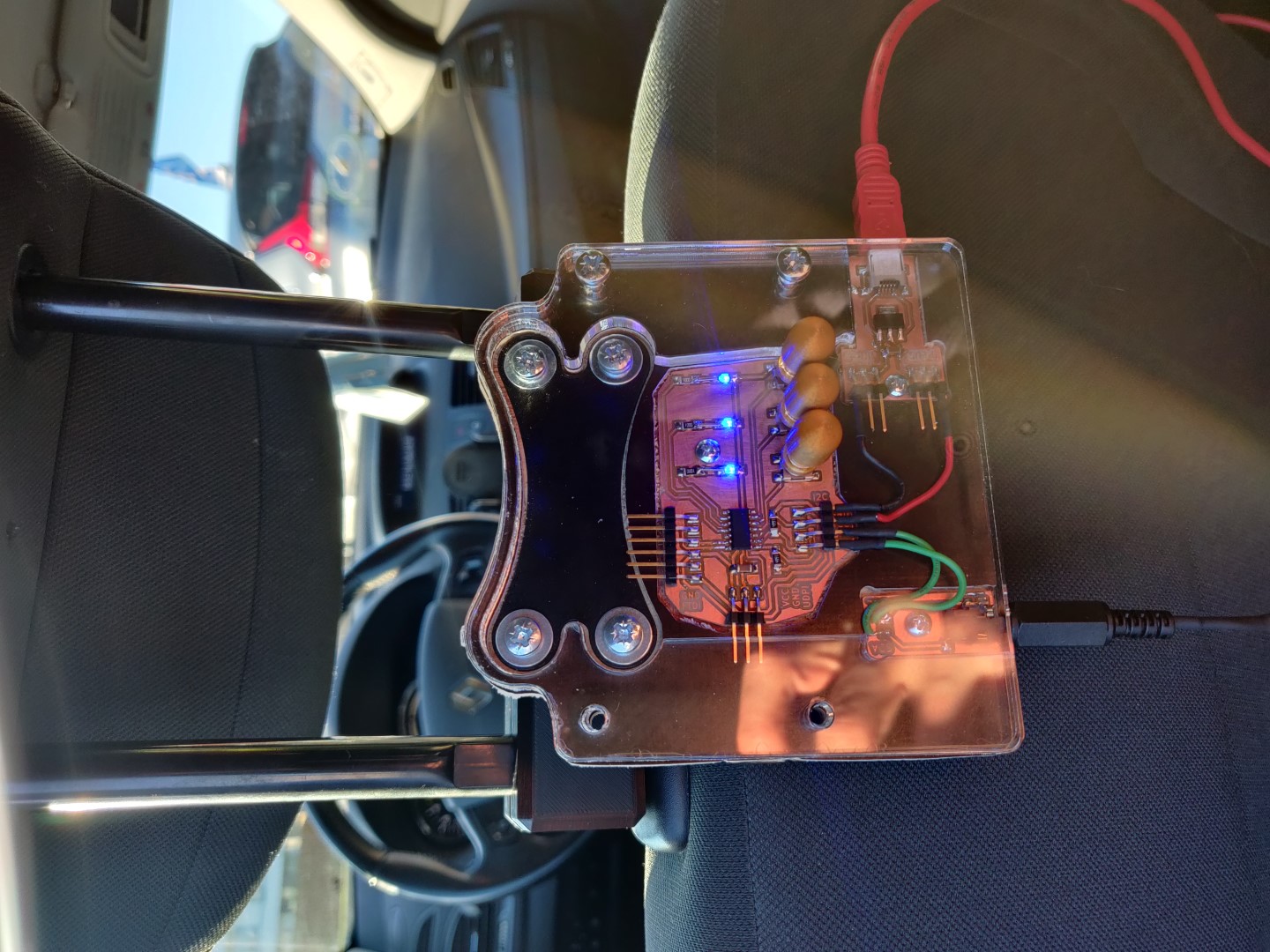

Árni Björnsson’s final project reveals everything with a transparent enclosure:

Wires hidden inside the structure of an LED-studded dress and integrated button, by Hafey Hallgrímsdóttir:

The work that comes after the first rough prototype

Food projects

- Inert materials

- Simple shapes that are easy to clean

- Smooth surface finish

- No crevices where water collects and bacteria can grow)

Design for safety

| Safety features: A colleague at an Icelandic company put two buttons far apart on a silicone molding press. The operator needs to push the buttons with both hands to operate the press, to eliminate the chance of getting their hand crushed. |  Image from OSHA

Image from OSHA

|

Usability

A QR code on the device that points to the documentation can be a nice touch.

Design 3D printed enclosures with shadow lines like they do for injection molding.

Would the device benefit from a small battery or capacitor to keep the clock running while it’s not connected to power?

Cable management

Svavar demonstrates how you can embed mesh fabric into 3D prints and make a cable carrier:

Links from Cedric Honnet:

“Cables can be protected by articulated, braided or hybrid wrappers”.

Vineet Padia has mentioned a way to document wiring harnesses.

It’s good for students to know that pogo pins and slip rings exist.

Design for repair

The amplifier unit in this PA speaker has a generous cable length, so Þórarinn could pop it out and troubleshoot:

Repair cafe (we host those at Fab Lab Ísafjörður, the atmosphere is great and it boosts community engagement with the lab)

Assembly

Asymmetrical hole placement, so that you can’t assemble the wrong way:

Injection mold designed and fabricated by Jóhannes Andrésson.

Pre-load things to eliminate rattle - use e.g. spring washers.

Documentation

Good ways to document electronics on a website:

- InteractiveHtmlBom

- Kicanvas (still in alpha, but you can embed KiCAD files on a web page)